- Shanghai Zhongshen International Trade Co., Ltd. - Two decades of trade agency expertise.

- Service Hotline: 139 1787 2118

Hidden cost traps in imported equipment procurement

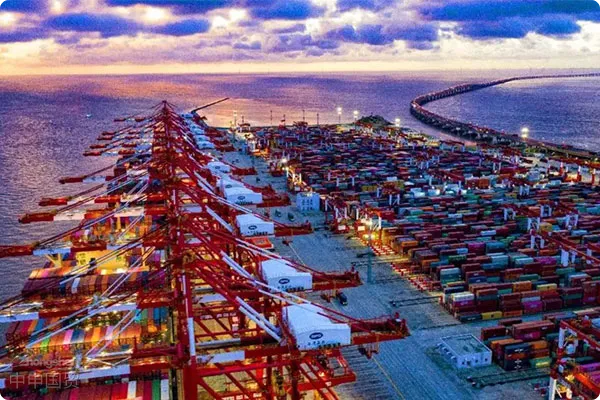

Customs data for 2025 shows that electromechanical equipment accounts for 38.7% of Chinas total imports, with nearly 30% of purchasers incurring additional costs due to improper operations. A certain auto parts manufacturer overpaid tariffs by 1.27 million yuan in 2023 when independently procuring a German production line due to HS code misjudgment, exposing the necessity of professional agency services.

Common risks and agency solutions

Risk 1: Supplier qualification traps

- A biotech company encountered the following when procuring French sterilization equipment in 2024:

- CE certification expired without renewal

- Original manufacturer authorization letter forged

- Agency service solution:

- EU Chamber of Commerce filing system verification

- Third-party notary on-site validation

Risk 2: Technical parameter misunderstandings

- A Jiangsu-basedphotovoltaicEquipment adaptation failure due to voltage frequency misunderstanding (50Hz/60Hz)

- Agents technical team provides:

- IEC standard conversion services

- Dual verification mechanism for equipment parameters

Core value system of professional agents

- Risk prevention and control system

- Contract clause review: Incoterms 2025 applicable clauses

- Transportation solution optimization: Ro-ro ship configuration for special-sized equipment

- Cost control module

- Tariff planning: ECFA rules of origin application

- Logistics integration: LCL cargo priority arrangement

Full process of agency service operations

- Demand confirmation stage

A certainMedical EquipmentAn import case shows that agent engineers discovered equipment-elevator size conflicts in advance through 3D model review, saving 800,000 yuan in modification costs

- Execution guarantee phase

- ATA Carnet processing (temporary import situations)

- Pre-shipment inspection of used mechanical and electrical equipment

Empirical benefit comparison analysis

- 2025 imported testing equipment data from a provincial laboratory:

- Independent procurement group: Average customs clearance time 27 days, anomaly rate 42%

- Agency service group: Customs clearance cycle shortened to 14 days, anomaly rate reduced to 9%

- Comprehensive cost composition comparison:

- Hidden cost proportion decreased from 19% to 6%

- Capital occupation cycle shortened by 40%

Criteria for selecting agency services

Key evaluation criteria:

- Special equipment operation qualifications (pressure vessels/radioactive equipment)

- Overseas service network coverage density

- Customs dispute resolution success rate

A food machinery importer synchronized equipment debugging with customs declaration through our Hamburg office in Germany, compressing project cycle by 30%. The value of professional agents lies not only in process handling but more in full-chain resource integration capabilities.

Related Recommendations

? 2025. All Rights Reserved. Shanghai ICP No. 2023007705-2  PSB Record: Shanghai No.31011502009912

PSB Record: Shanghai No.31011502009912